MWM Schmieranlagen will attend to EMO 2023, world's leading trade fair for machine tools, automation and metalworking, that will be in Hannover from...

In many industrial environments, policies are in place to contain lubricant consumption, reduce costs and environmental impact.

In line with the market requirements in the field of MQL applications, MWM Schmieranlagen has specially developed and patented a series of compact and cost-effective sensors for continuous monitoring of MQL systems and for mist lubrication detection.

The IFX-F sensor can be provided for industrial use to monitor several mist lubrication systems in order to check over time that lubricant consumption remains as expected. Without being over-consumed due to manipulations or unexpected changes in flow rate.

With the IFX-F mist sensor, it is possible to control not only the operation of the lubrication device (functional control), but also to measure the quantity of lubricant sprayed precisely and proportionally. This is because the IFX-F sensor has an output with a mA signal. The IFX-F mist sensor is therefore not a simple 'pass, don't pass' control, but rather a very precise sensor that measures the lubricant quantity in relative values (which can be reported as an absolute value in ml/h).

The IFX-F sensor can be mounted on transparent pipes of different diameters (6, 8, 10 and 12 mm) and continuously and accurately measure any change in flow rate, verifying the correspondence between the set lubrication parameter and the corresponding value in mA. The sensor has a very fast response time (less than one second) and can monitor multiple changes in lubrication parameters, even in the case of MQL systems with automatic lubricant flow variation.

The IFX-F mist sensor also makes it as easy to control lubrication, both in fixed flow systems, and on machines where a change in flow rate is necessary. For example for internal MQL lubrication on machine tools, where there are several tools of different sizes.

For example, in machining centres, during commissioning where it is planned to work with automatic changeover of several different tools; the control parameters for lubrication of each type of tool are established. Any variation in the amount of lubricant over time, in access or in defect, can be monitored and verified with the settings programmed at the time of commissioning the machine tool.

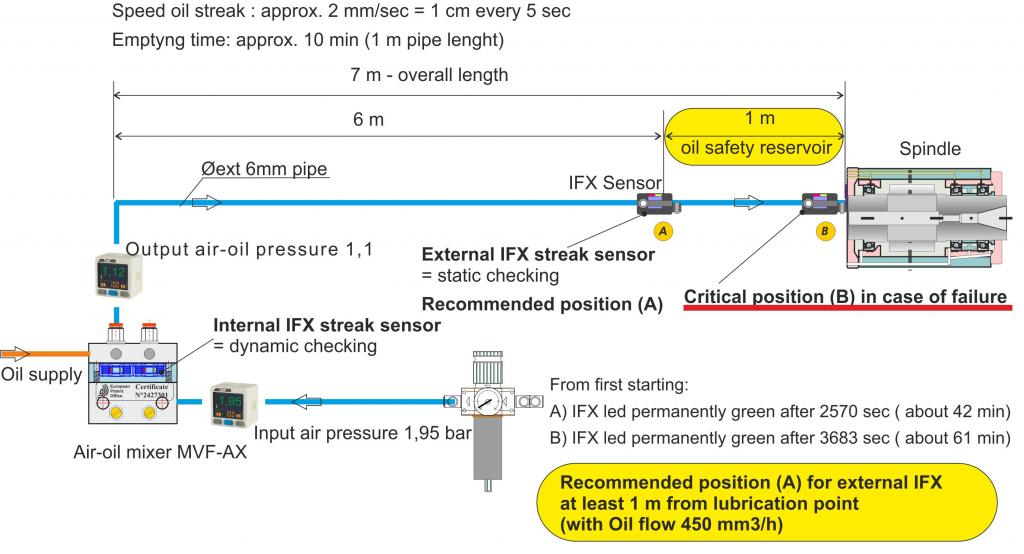

Application of optical streak sensors in air+oil lubrication systems

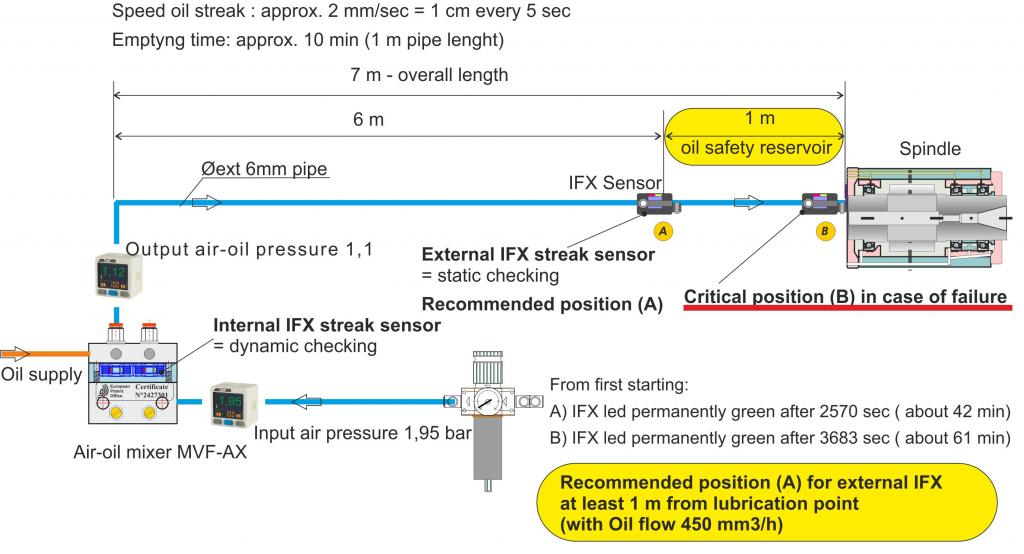

Sensors can be mounted in retrofit procedures in order to verify the working of the air+oil mixers that have been previously installed. In this case they are mounted directly at mixer outlet.

Please consider that in this case the sensor controls a flow that is never steady because the lubricant dosing, in single-line systems, takes place cyclically at timed pulses.

So we have to distinguish between a dynamic type control (signal at every lubrication cycle) or static control (signal nearly uninterrupted).

We have the following options:

- Dynamic control: with sensor type IFX-S08 mounted inside the mixer (MVF-AX)

- Dynamic control: when the sensor (type IFX-C04 or C06) is outside the mixer, but at a distance of max. 10 cm.

- Static control: when the sensor (type IFX-C04 or C06) is outside the mixer and it is positioned to a distance of more than 1 mt.

In cases 1 and 2 the sensor will respond changing the status (LED green and then red) at every lubrication cycle, advising that the lubricant dosing took place properly. In case 3, the signal (green LED) is always on, provided that the lubricant flow rate (the oil streak) is enough and uninterrupted: for example, with a sensor positioned at 3 mt. from the mixer and a lubricant volume of at least 300 mm3/h, with an air flow not higher than 50 Nl/min.

A lower quantity of lubricant volume, or a higher air flow rate, can cause an unstable signal owing to a too limited and irregular flow for the optics of the sensor, but however valid for the needs of the lubrication point. This must be taken into consideration reasonably in the signal control management.

On the basis of the experience consolidated in the practical field, it is preferable to recommend a dynamic control, since this type of control is independent from the dosed volume and guarantees the control of every single cycle (“miss shot”).

The static control is used as redundant control, as guarantee of the lubricant presence in the final part of the pipes (see also video clip “redundant sensor”)

Related products

The new MWM system for air+oil lubrication, setting new standards for minimal lubrication of bearings for high speed, for use with the specific ATEX zones 2-22. The integration of patented products like air+oil mixers with integrated optical sensors, digital pressure sensors, and advanced digital PLC controlled, allow 100% control of all important parameters. Visual feedback and electronic reporting error available for the NC machine, to ensure minimal lubrication with reliable 100% security in the start-up and operational.

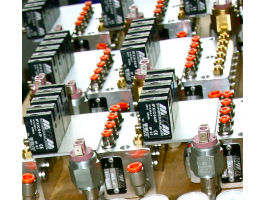

Lubrication of 12 points for 6 GMN spindles.

Equipped with 6 oil+air mixers MVF-A and back-up mixer, with internal optical oil streak sensors (European Patent Certif. N°2427301).

With programmable electronic control unit.

The lubrication units type ZX are complete systems which produce the oil+air mixture, by cyclically dosing small and precise amounts of oil in a continuous air flow.

The unit is controlled by an internal PLC which enables a precise programming of lubrication cycles; the delivery of the oil+air mixture is monitored by optical oil streak sensors placed at the outlets of the mixer.

The monitoring elements communicate with the lubrication unit PLC, which is connected to the central unit of the machine.

The unit is assembled inside a metallic box and has filters both on the air line and on the oil line. Specifically designed for the lubrication of several spindles in simultaneous working.

The integration of patented optical oil streak sensors with digital pressure sensors and advanced PLC functions allows 100% control of all important parameters.Visual and electronic feedback with simple warning signal is available to the machine control, to assure reliable oil+air minimal quantity lubrication and 100% safety while working.

The new air+oil lubrication system presented by MWM Schmieranlagen sets new standards for minimal quantity lubrication of bearings in high-speed/power spindles for machine tools.

The integration of patented optical sensor technology with digital pressure sensors allows 100% control of all important parameters. Moreover a dedicated PLC, connected with multipolar connection, allows automatic management of lubrication parameters and control system, in order to ensure a 100% safe lubrication.

The system provides a visual and instrumental feedback, through a simple alarm signal, for communication with machine.

This ensures a reliable MQL at starting and 100% safety during operation.

The system is provided with a mixer type MVF-A with integrated optical sensors (International Patent) available in versions from 1 up to 6 outlets.

A monitoring system with dual oil streak detection sensors (optical sensor IFX) is considered as redundant. Redundancy is the duplication of components able to perform the same function, with the intention of increasing the system’s reliability. In this way a faulty element does not cause the system’s failure because the particular function can be performed by another element. A “failure-safe” system does not imply that failure is impossible/improbable, but rather that the system's design prevents or mitigates unsafe consequences in the event of a failure.

MWM has developed a new lubrication system with dual oil streak optical sensors, able to deliver extra safety to any air-oil lubrication process for spindle bearings.

A first optical flow sensor, IFX-S08, mounted inside the MWM’s patented air-oil mixer MVF-A, performs in-line oil streak dynamic monitoring. One additional optical flow sensor IFX-C, mounted external to the pipe in a position away from the mixer but close to the spindle, performs static monitoring. This external sensor gives the operator full visibility over the continuity of the oil flow, as it is detected near the lubrication point. In case of a failure, the sensor gives an alarm signal and may stop the machine, to avoid any damage.

The meanings for dynamic and static monitoring are respectively as follows:

- dynamic monitoring: during the lubrication cycle, when the pump feeds the lubricant to the air-oil mixer, the sensor detects the presence of lubricant (green LED). Once the first “wave” of oil is passed by, the air flow cleans the air duct and therefore the oil streak sensor does not detect any oil passage (red LED)

- static monitoring: in normal operating conditions, a continuous streak of oil is transported by the air flow towards the lubrication point (spindle). The sensor mounted on the pipe, detects the presence of lubricant in a continuous mode (green LED). When this streak is no longer continue, the led turns red.

It is recommended to mount the external sensor IFX-C at not less than 1 m distance before the spindle, so that the residual pipe length may act as an oil safety reservoir. In case the external sensor detects no oil streak, there will be still sufficient time (10 minutes as a minimum) before the oil reservoir comes to its end. Therefore it will be possible to make a prompt intervention, avoiding the risk of leaving the spindle in operation without lubricant.

Instead, placing the sensor right before the spindle would be a critical choice: in case of failure there will be no residual pipe length which can be used as an oil reservoir for a short period of time. However, the redundant system will generate a (double) alarm signal and will immediately stop the machine.

Lubrication of 12 points

for 6 GMN spindles.

Equipped with 6 oil+air mixers MVF-A and back-up mixer, with internal optical oil streak sensors (European Patent Certif. N°2427301).

With programmable electronic control unit.

The lubrication units type ZX are complete systems which produce the oil+air mixture, by cyclically dosing small and precise amounts of oil in a continuous air flow.

The unit is controlled by an internal PLC which enables a precise programming of lubrication cycles; the delivery of the oil+air mixture is monitored by optical oil streak sensors placed at the outlets of the mixer.

The monitoring elements communicate with the lubrication unit PLC, which is connected to the central unit of the machine.

The unit is assembled inside a metallic box and has filters both on the air line and on the oil line. Specifically designed for the lubrication of several spindles in simultaneous working.

The integration of patented optical oil streak sensors with digital pressure sensors and advanced PLC functions allows 100% control of all important parameters.Visual and electronic feedback with simple warning signal is available to the machine control, to assure reliable oil+air minimal quantity lubrication and 100% safety while working.

The new MWM system for air+oil lubrication, setting new standards for minimal lubrication of bearings for high speed, for use with the specific ATEX zones 2-22. The integration of patented products like air+oil mixers with integrated optical sensors, digital pressure sensors, and advanced digital PLC controlled, allow 100% control of all important parameters. Visual feedback and electronic reporting error available for the NC machine, to ensure minimal lubrication with reliable 100% security in the start-up and operational.

Air+oil minimal lubrication offers the most appropriate solution for the lubrication of high speed bearings without overheating due to an excess of lubricant.

|

MWM designs and produces Air+Oil lubrication systems with optical sensor.

Air+Oil lubrication units, preassembled MQL units ready for use.

|

IFX programmable optical streak sensor

|

|

The main fields of application for MWM technology are:

Machine tools, cutting and grinding machinery for the steel industry.

Grinding and polishing machines for marble, wood and metals, textile machinery.

Rotating machines for power cables and steel ropes and any other machinery where bearings have to work at high speed and/or high power. |

Boring &Milling Machines

Machining Centers

Grinding Machines |

Related products

The 28th BIMU in Milan showed a very qualified offering of Machine Tools. MWM solutions were present on many machines, with the most advanced units of minimal quantity Air & Oil lubrication units and systems.

Hall 13 on stand B16-D17, SIRMA presented the CNC lathe CINCOM K16E-VII, with 5 axis (plus 2 axis C). It was fitted with a LUBRIX 500 system for Internal Minimal Quantity Lubrification in the deep drilling tools.

It is equipped with a special custom made MWM A+O minimal lubrication system, to satisfy all the challenging requirements of the precise and monitored minimal lubrication pf spindles and axis. With the MWM A+O mixers MVF-A with integrated optical sensors (MWM international patent).

![]()

Other applications of MWM systems were installed on Work centres and big Boring Machines in Hall 9.

* The European project Integ-Micro is an ambitious initiative that can build 5 new platforms to redesign the state of the industry, this special attention from the European Commission is due to the fact that the micro-machining technologies play a increasingly important role in various industries, from electronics to biomedicine and others, and are considered strategic for the development and growth of the European manufacturing