MWM Schmieranlagen is the first company in Italy to have developed compact Oil+Air Lubrication Units for minimum quantity lubrication (MQL) with patented electronic devices for control of the dosed air+oil supply. In order to realize an efficient lubrication of high speed ball bearings, only MQL system can ensure the minimun lubricant quantity, avoiding overheating.

The MQL finds application in processes like HSC (High Speed Cutting) for example in the aeronautic industry, as well as in the car industry, in mould working and other sectors. The MQL-MWM products family consists of a wide range of units and accessories for different kind of applications in the machine tools field.

The main fields of application for MWM technology are high speed bearings used in spindles for machine tools.

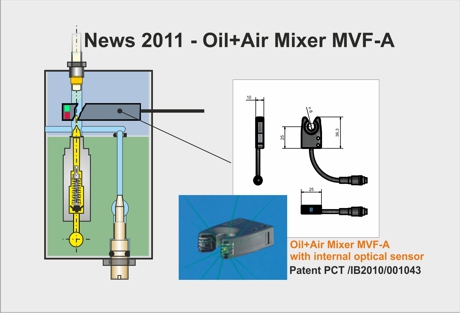

![]()

IFX sensors, for a reliable/safe lubrication

The Optical Streak Sensor applied directly on the Oil+Air Mixer can guarantee the outgoing of the air-oil mixture from the mixer. The lubricating flux pass through the sensitive part of the sensor inside a transparent tube; the image variation is detected from the electronic receiver of the element so that any lack of flux causes an alarm output signal. IFX sensors are programmable and the output signal can be managed by a control unit.